We are pleased to introduce our ranges of Asphalt Mix Plant as the brand of Gujarat. Having high production set-ups in well developed area of ahmedabad, we are able to get benefits of so many facilities like expert labor, electricity, transportation and many more. We are being providential been capable to develop high quality Asphalt Mix Plant in ahmedabad.

Why Ahmedabad is Emerging as a Hub for Asphalt Mix Plants?

- Since it is connected to Gujarat’s industrial areas, Ahmedabad has developed into a prominent manufacturing and supply base for asphalt mix plants in both the Indian and international markets.

- The city contains top-class engineering expertise, which includes talented mechanical and civil engineers who specialize in heavy construction equipment.

- The asphalt plants built in Ahmedabad present significant export value to customers throughout Africa, Southeast Asia, and the Middle East.

The market will experience growth from 2026 onward

Large-scale government initiatives under Bharatmala Pariyojana, along with Smart City Missions, generate an extensive demand level.

The exporting activities of Ahmedabad manufacturers continue to rise while their superior asphalt plants find buyers in Kenya, Nigeria, the UAE, Bangladesh, and Sri Lanka.

The increasing concern for environmental construction brings forward both green asphalt solutions and recycling solutions in the market.

Future of Asphalt Mix Plants in India

Road construction activity receives public sector backing through three key initiatives including Bharatmala Pariyojana, PM Gati Shakti Yojana and Smart Cities Mission.

Resources and green technologies that focus on recycled materials continue to expand their use in asphalt production.

Low-emission and energy-saving plants present an increasing market demand that Ahmedabad Manufacturers are actively prepared to meet.

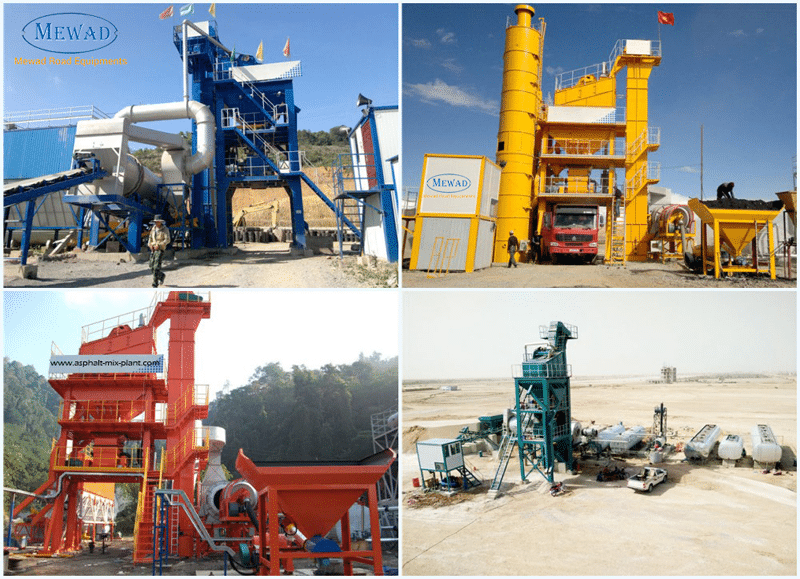

What We Offer as a Top Asphalt Mix Plant Manufacturer in Ahmedabad?

Stationary Asphalt Batch Mix Plants – Ideal for large-scale infrastructure projects.

Mobile Asphalt Drum Mix Plants – Perfect for quick relocations and remote project sites.

The Recycling Asphalt Plants (RAP) offer environmentally responsible solutions to reuse asphalt materials.

The mixing process receives accurate control through PLC/SCADA automation systems.

Energy-efficient burners and thermal insulation for reduced operational costs.

Dust and emission control systems are compliant with CPCB standards.

Asphalt mix facilities exist in multiple capacities ranging from 60 TPH to 200 TPH and above.

The system allows clients to modify their configurations according to their needs.

Integration with hot recycling units.

Production runs through dust-controlling Baghouse filters that ensure clean and filtered dust results.

Asphalt Mix Plant Manufacturer in Ahmedabad

Ahmedabad has become one of the biggest industrial machinery-producing centers, and one of the most reliable solutions is the Asphalt Mix Plant. These plants are designed to provide high-quality construction of roads and to guarantee proper mixing, heating, and production of asphalt according to international standards. An asphalt batch mix plant is very reliable and productive, whether in national highways or city roads, or large-scale infrastructure projects.

Being one of the Asphalt Mix Plant Manufacturers in Ahmedabad, we have a complete variety of asphalt plants designed using advanced technology and constructed to serve long-term. Contractors, builders and government project developers in India and abroad have a large preference for our plants.

Being one of the leading asphalt mix plant manufacturers, we are oriented to innovation, durability, and high engineering. In Ahmedabad, we have a manufacturing plant that ensures top quality control to satisfy the demands of the local and international road construction markets.

Key Features:

- Energy-saving dryer and burner systems.

- Pollution control and dust collection devices.

- Easy installation through modular construction.

- High production capacity

- Strong and anti-corrosive parts.

- No or limited-maintenance smooth running of the plants.

High Quality Asphalt Batch Mix Plant Manufacturer in Ahmedabad

Our batch mix asphalt plant is developed to manufacture quality hot mix asphalt accurately. Necessary elements of the plant include:

- Cold Aggregate Feeders

- Dryer Drum

- Burner System

- Vibrating Screen

- Hot Bins

- Mixing Unit

- Control Cabin

- Filler Storage & Feeding

- Bitumen Tanks

Our asphalt plants have high automation and user-friendly control systems that provide constant weighing, optimal mixing cycle, and uniform production.

We are known as a trusted Asphalt Mix Plant Supplier and Exporter and have been supplying plants to various countries in Asia, Africa, Gulf countries, and Europe. We have an export-oriented design assuring the international performance standards and safety.

Reasons Why We are a Preferred Exporter?

- International-quality manufacturing

- Support by providing a timely delivery and full documentation.

- Customization option to climatic conditions in foreign locations.

- On site installation and training.